Services

From Design to Beautiful Anodised Components

SACO provides end-to-end manufacturing for premium aluminium components, offering aluminium anodising, aluminium pressing, in-house tooling and precision assembly. Our UK-based production ensures reliable turnaround and consistent quality, delivering bespoke aluminium components tailored to brand requirements.

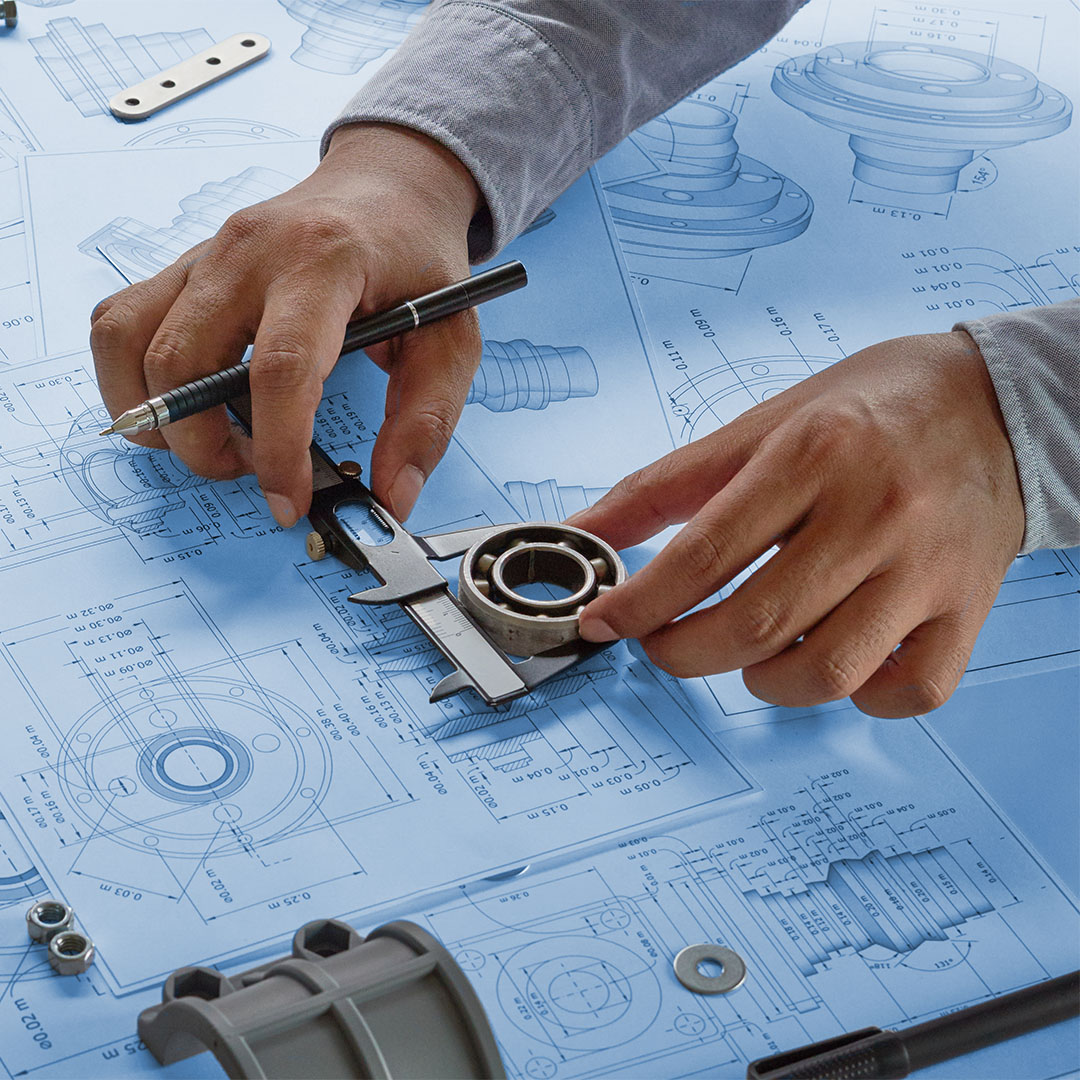

Design

- Early-stage feasibility support

- Artwork interpretation for embossed/debossed features

- Safe-edge design for consumer protection

- Knurling, ribs, flutes and visual detailing

- Dimensional optimisation

- Technical drawings and prototyping

Tooling

- In-house toolroom

- Custom tooling for bespoke components

- Multi-stage deep draw tooling

- Bruderer progression tooling

- Tool trials, adjustments and optimisation

- Known for rapid tool turnaround and precision

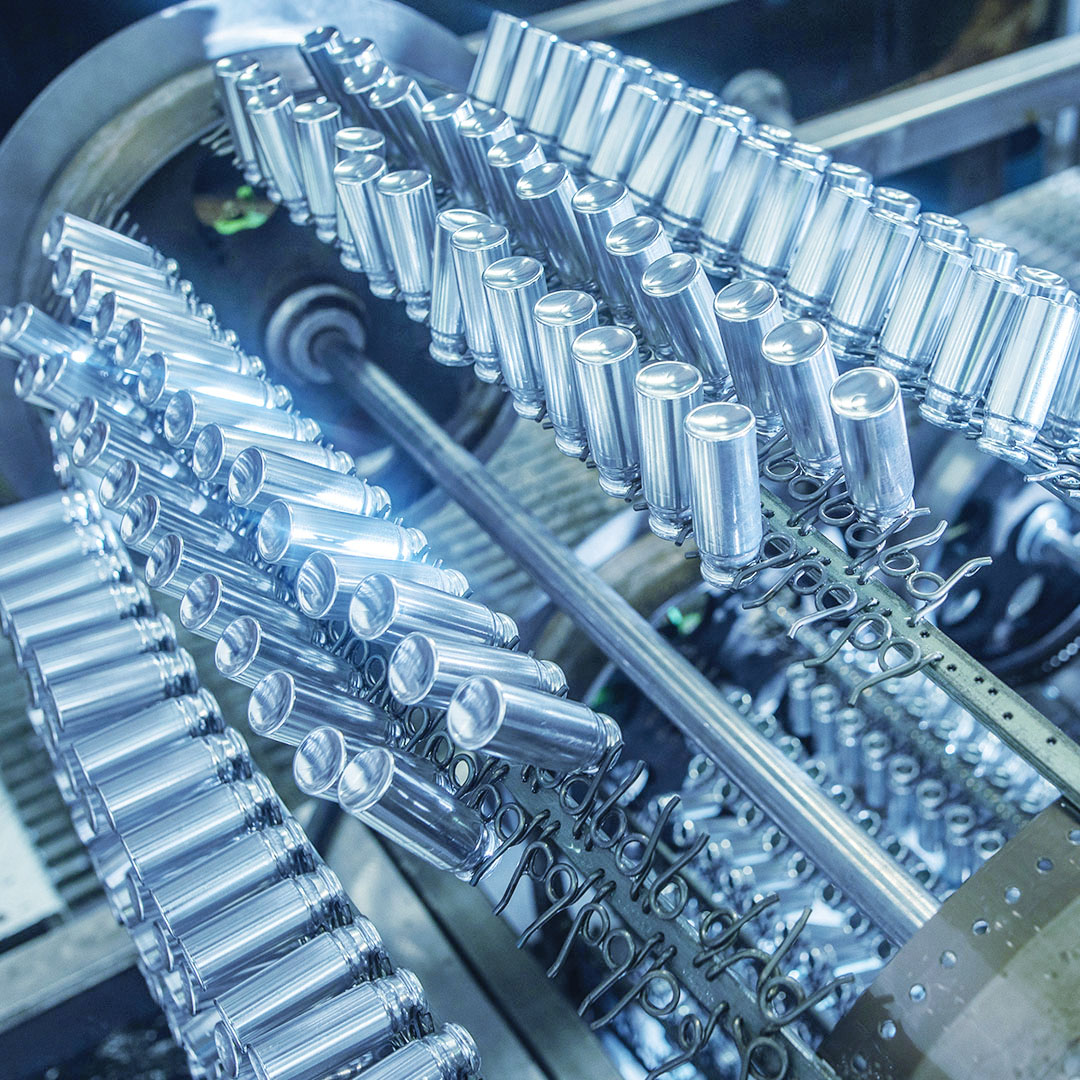

Pressing

Deep Draw Transfer Pressing (10–12 stage)

- For collars, caps, lipstick sleeves, actuators, jar caps, diffuser collars

- Sizes from 10mm-60mm diameter and 10mm-80mm height

Bruderer Progression Pressing

- Rapid precision pressing for high-tolerance parts

Embossing & Debossing

- Top-face artwork and radial debossing

Decorative Mechanical Finishes

- Diamond rolling, satin bands, knurling, fluting

Material Gauge

- 0.3mm to 0.8mm standard aluminium gauge

- Bespoke gauges available

Anodising

- Rack anodising, each part held individually for highest consistency

- Belt-driven universal holding method, equal timing and controlled exposure

- Single-product processing, prevents cross contamination

- Bright, satin, matt and custom finishes

- Batch colour consistency

Pharmaceutical-grade anodising for cans and ferrules - Traceable chemistry and controlled dosing

Assembly

- Automated and semi-automated assembly

- Multi-part component alignment

- Plastic inserts, fit-control and force testing

- Clean, controlled assembly environments

Project Management

- Dedicated account manager for every customer

- 24-48 hour order acknowledgement

- Strong OTDIF performance

- Project planning updates throughout development

- Fast-track industrialisation: tooling held in press awaiting customer approval

- Reserved capacity for rapid production once samples are approved

Responsibility

- Responsible anodising chemistry management

- Efficient pressing processes to minimise waste

- Recycling of all aluminium scrap

- Compliance with UK and EU regulations

- EcoVadis Bronze certified business

Contact Us

Launching a New Product or Need Help Developing a Bespoke Aluminium Component?

We support brands from concept through to final assembly — offering innovative design, bespoke aluminium components and reliable UK manufacturing. If you have a specific enquiry please use our contact page.